Recruitment hotline:17621088007

Sales hotline15902157027

Properties of fused quartz ceramics

Fused quartz ceramics have the following advantages:

1. small thermal expansion coefficient

Between room temperature and 800℃, the coefficient of thermal expansion of pure quartz ceramic system is 0.54×10-6/℃, which is the same as the coefficient of thermal expansion of quartz glass, so it has good volume stability, thermal shock stability and high temperature creep resistance, so that it can be between 1000℃ and 20℃ air or water, and the number of hot and cold exchange is greater than 20 times.

2. Stable chemical properties

Quartz ceramics can be in direct contact with hydrochloric acid, sulfuric acid, nitric acid and other three strong acids for a long time without any chemical changes;Secondly, quartz ceramics do not react with lithium, sodium, potassium, uranium and other corrosive metal melt;Quartz ceramics can also be resistant to high temperature glass liquid corrosion.

3. stable thermal conductivity

The thermal conductivity of quartz ceramics is very low and almost unchanged from room temperature to 1100 ° C.

4. superior high temperature mechanical properties

When the temperature reaches 1000℃, the bending strength and other physical and mechanical properties of fused quartz ceramics increase with the increase of temperature, and the increase value is as high as 33%.This characteristic is different from other ceramics, the main reason is that the plasticity of fused quartz ceramics increases with the increase of temperature and the brittleness decreases, which is conducive to the application of fused quartz ceramics at high temperatures.

5. the body drying, burning shrinkage is small

The shrinkage rate of fused quartz ceramics in drying and firing is generally less than 5%, so it is conducive to the preparation of large-size products.

6. good dielectric properties

Fused quartz ceramic has low dielectric constant and low dielectric loss, and the change of dielectric constant and dielectric loss Angle tangent value with temperature is much lower than other high temperature ceramics, which can meet the requirements of low attenuation and low distortion of radar wave, and is an ideal material for missile and radar radomes.

7. good anti-nuclear radiation performance

Fused quartz ceramics are amorphous and have a small coefficient of thermal expansion, so they have a relatively stable structure and strength under radiation conditions, unlike other materials that will be transformed into amorphous structures, which makes them widely used in the atomic energy industry and radiation protection laboratories.

Preparation technology of fused quartz ceramics

At present, the molding processes of fused quartz ceramics include grouting molding, injection molding, isostatic pressing molding, centrifugal casting molding, watering molding, wax injection molding, semi-dry molding, hot pressing molding, etc., among which the commonly used in industry are grouting molding and injection molding.

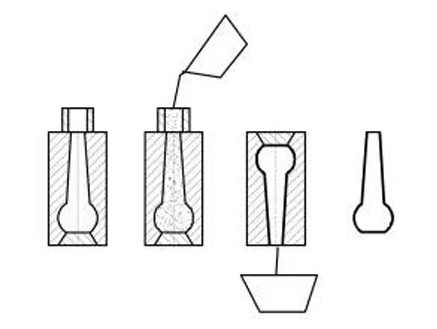

Grouting molding: grouting molding is the molten quartz ceramic particles suspended in water to make slurry, and then injected into the gypsum mold, after natural or forced drying, you can take out the blank.There are many factors that affect grouting molding, including slurry viscosity, mold material and structure, and grouting technology.The process includes slurry preparation, mold preparation and grouting.

Grouting molding diagram

The grouting molding process has high production efficiency and is suitable for large-scale industrial production.However, compared with the traditional mud, quartz ceramic mud has the characteristics of high solid content, strong thixotropy, poor fluidity and suspension, so the process conditions are harsh when casting large size or solid products.

Injection type:It is a new technology developed on the basis of traditional grouting molding. In the 1990s, it was proposed and developed by Omatete of the National Key Laboratory of Oak Ridge in the United States. It combines the traditional molding process with the theory of organic chemistry.So it is also called gel injection molding.

This process equipment is simple, the body strength is high, shrinkage, easy to manufacture complex shape of fused quartz ceramic products, and the molding efficiency is higher than that of grouting molding, and it has developed rapidly in the past 20 years.The fused quartz ceramic products of grouting molding have the characteristics of high density, dense structure, high strength, good wear resistance, anti-erosion, etc., and are suitable for manufacturing products with simple shape and high density and strength requirements.

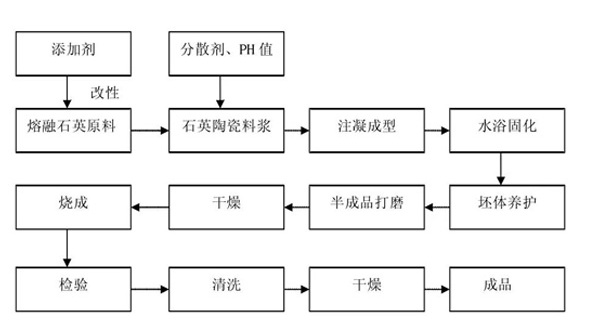

Due to its near-net size production and complex shape products, it has become a new way to prepare complex ceramic products. The specific process is mainly divided into slurry preparation, curing and demudding, drying and stripping, and sintering products. The specific process flow chart is as follows.

Injection process flow chart

Influencing factors of injection molding

Slurry preparation is the key step in the whole process of injection moulding.The solid content of the slurry determines the bulk density of the green billet, and the viscosity of the slurry determines whether it can be formed, so it is very important to study the preparation and performance of the slurry.

Solid content

The preparation of high density and low defect billet by injection moulding is closely related to the content of solid phase.Solid content refers to the ratio of fused quartz powder to the volume of slurry.Theoretically speaking, the higher the solid phase content, the better the compact performance of the prepared green.The higher the density of the body means the increase of its strength, and the higher the solid phase content, the greater the strength of the body.

But in fact, as the solid content increases, the viscosity increases.This is because with the increase of solid phase content, the movement between particles is more difficult, the viscosity increases, and the fluidity becomes worse.Generally speaking, the solid phase content of high solid phase slurry is more than 50%.

pH value

The pH value of ceramic powder slurry is its acid-alkaline, and the different pH value and the different charging conditions on the surface of the powder will change its Zeta potential.The change of Zeta potential directly affects the electrostatic repulsion between particles, thus affecting the stability of slurry.

At the same time, pH value is also a very important factor affecting slurry viscosity, so pH value is essential to the study of slurry properties.

Theoretically, the greater the Zeta potential, the better the dispersion performance, but for fused quartz ceramic slurry, with the increase of pH value, resulting in the increase of double electric layer charge, which will bind more water, resulting in a decrease in the amount of free water outside the colloid;The pH value is small, although the potential is small, but because of the thin double electric layer, the free water outside the colloid increases, so the viscosity will be smaller.

dispersant

Dispersant plays a key role in the preparation of slurry system with high solid content. Dispersant can prevent aggregation between particles and reduce the amount of water in slurry to a certain extent, so dispersant can also be called water reducer.

The amount of dispersant has a great impact on the dispersion effect of the slurry, if the amount of dispersant added is too small, it will lead to the surface of the fused quartz powder particles can not be completely absorbed by the dispersant, so as to achieve the dispersion effect, this phenomenon is called unsaturated adsorption state.

Too much dispersant will lead to excessive adsorption on the surface of fused quartz powder particles, resulting in a thick double electric layer to bind more water, resulting in poor fluidity, while the remaining unadsorbed dispersant particles will be bridged by polymer chains, thereby inhibiting the free movement between particles, resulting in greater slurry viscosity, this phenomenon is often called supersaturation state.

Guangdong Honglei New Material Technology Co., Ltd

Addr:Intersection of Gongye San Road and Ping'an Road in Linjiang Industrial Park, Jiangdong New Area, Heyuan City, Guangdong Province

Tel: (0762) 330 6669

Email: info@hlnmt.com

Postal code: 517475

Contact WeChat